Morse Mfg. Co., Inc. is pleased to have publications utilize images and copy.

For hi-res images and express permission,

please contact Morse at: inquiry@morsedrum.com

Thank you,

Ralph Phillips,

Marketing Manager

Morse -- “The Specialist in Drum Handling” – has originated most drum handling advancements world-wide, and offers the widest product line of over 100 items, plus custom engineered versions, and provides users with the most extensive and expert dealer support network.

For hi-res images and express permission,

please contact Morse at: inquiry@morsedrum.com

Thank you,

Ralph Phillips,

Marketing Manager

Morse -- “The Specialist in Drum Handling” – has originated most drum handling advancements world-wide, and offers the widest product line of over 100 items, plus custom engineered versions, and provides users with the most extensive and expert dealer support network.

Video about Morse Manufacturing Company

Sample News Releases

Save Time and Money with Bead Blasted Stainless Steel Drum Handlers

Now you can get dozens of Morse stainless steel drum handlers with bead blasted finishes. Morse quality mobile drum handlers, fork attachments, below-hook handlers, drum mixers -- almost all of Morse’s over 100 stainless steel products are now available with bead blasted finishes. They are cost-efficient and deliver faster.

Now you can get dozens of Morse stainless steel drum handlers with bead blasted finishes. Morse quality mobile drum handlers, fork attachments, below-hook handlers, drum mixers -- almost all of Morse’s over 100 stainless steel products are now available with bead blasted finishes. They are cost-efficient and deliver faster.

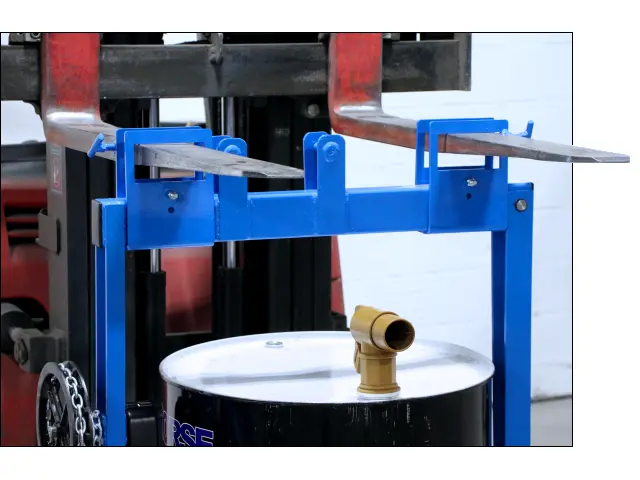

New, Low Cost, Fast, Safer: Finally, a safe, easy-to-use solution for handling drums using BOTH a below-hook hoist AND a forklift

Avoid accidents resulting from operators using bare forks to handle drums, or misusing drum handling equipment. Morse Fork Pockets quickly slip on, bolt-down and your below-hook drum handler is forks-ready. Now your drum handling can go seamlessly from below-hook to forks, and from forks to below-hook.

Check out our Fork Pocket Kit demonstration video for this new accessory that speeds productivity with added safety! See for yourself – and it is designed, built and tested in the U.S.A.

Avoid accidents resulting from operators using bare forks to handle drums, or misusing drum handling equipment. Morse Fork Pockets quickly slip on, bolt-down and your below-hook drum handler is forks-ready. Now your drum handling can go seamlessly from below-hook to forks, and from forks to below-hook.

Check out our Fork Pocket Kit demonstration video for this new accessory that speeds productivity with added safety! See for yourself – and it is designed, built and tested in the U.S.A.

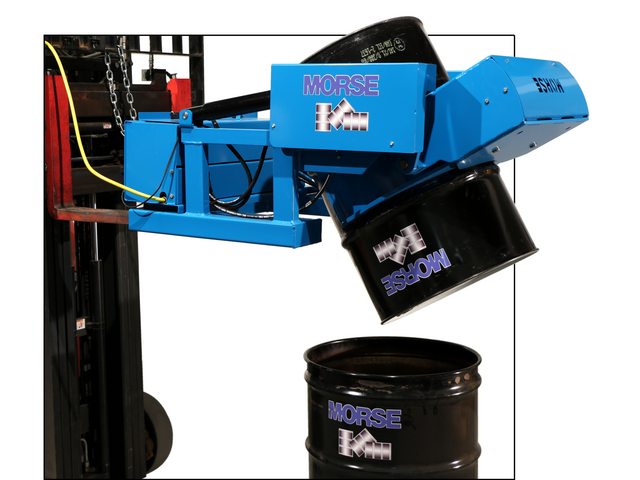

GRIP+GOTM

Power-Grip Fork Mount Drum Handler

With the new GRIP+GOTM drum handler forklift attachment, an operator can lift, move and pour a drum quickly and securely without leaving the truck seat/controls. A steel, poly or fiber drum can be completely inverted, rotating forward 180 degrees. The operator has accurate control of the drum tilt function throughout the range of motion, from upright to fully inverted, and at every selected height with pendant or wireless controls. Drums of various sizes can be easily grasped from off the floor, a pallet, racking and trucks.

Power-Grip Fork Mount Drum Handler

With the new GRIP+GOTM drum handler forklift attachment, an operator can lift, move and pour a drum quickly and securely without leaving the truck seat/controls. A steel, poly or fiber drum can be completely inverted, rotating forward 180 degrees. The operator has accurate control of the drum tilt function throughout the range of motion, from upright to fully inverted, and at every selected height with pendant or wireless controls. Drums of various sizes can be easily grasped from off the floor, a pallet, racking and trucks.

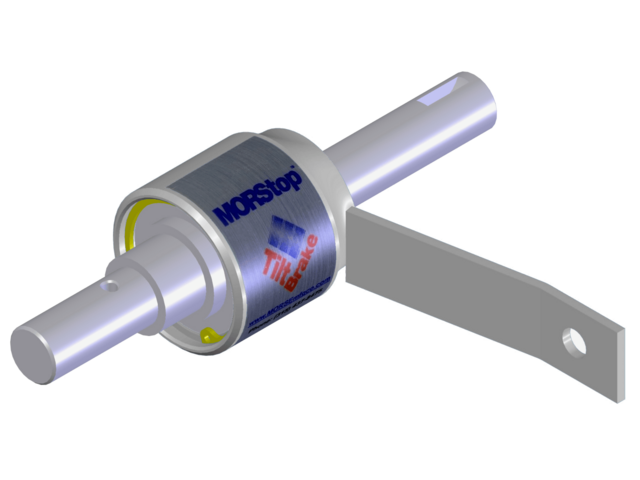

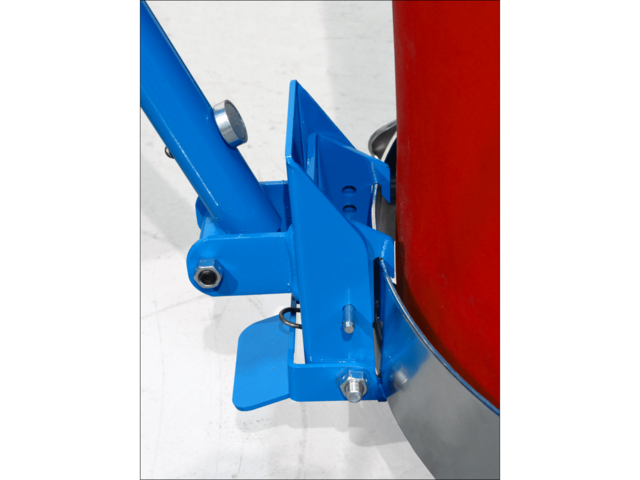

MORStopTM Tilt-Brake

The MORStopTM Tilt-Brake automatically stops and holds the drum at every tilt angle. It is a compact anti-backdrive device that functions smoothly and quietly in both directions.

Without the Tilt-Brake, a heavy unbalanced drum may tilt/rotate dangerously out of control - requiring operators to manually lock the pull chain or hand crank to prevent unwanted drum rotation. The Tilt-Brake eliminates this need, enhancing productivity and safety.

The Factory Installed MORStopTM Tilt-Brake Option is available on many manual tilt Morse models.

The MORStopTM Tilt-Brake automatically stops and holds the drum at every tilt angle. It is a compact anti-backdrive device that functions smoothly and quietly in both directions.

Without the Tilt-Brake, a heavy unbalanced drum may tilt/rotate dangerously out of control - requiring operators to manually lock the pull chain or hand crank to prevent unwanted drum rotation. The Tilt-Brake eliminates this need, enhancing productivity and safety.

The Factory Installed MORStopTM Tilt-Brake Option is available on many manual tilt Morse models.

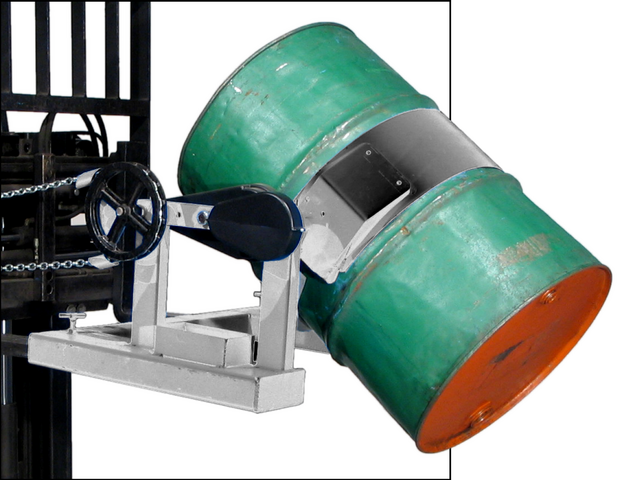

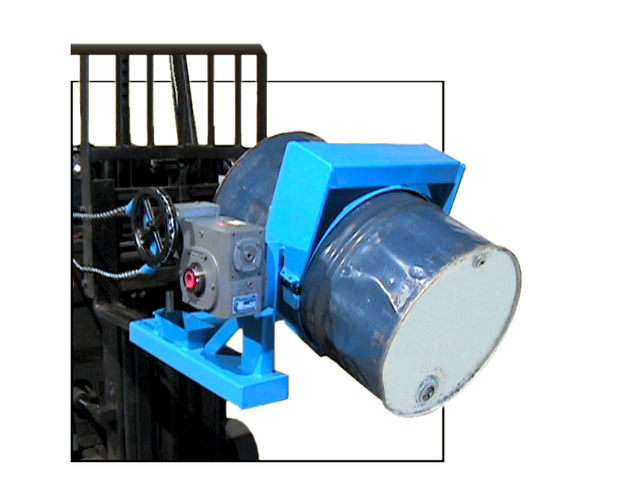

Forklift-Karriers convert your fork truck into a drum handler

With a Morse forklift attachment, you can easily lift, move and pour a 55-gallon (210 liter) steel drum, with options to handle various other types and sizes of drums. Models are available to dispense a drum weighing up to 1134 kg (2500 Lb.).

Choose from manual tilt controls, powered tilt controls by pendant, or wireless controller as shown.

Install the correct MORCINCHTM Kit to safely handle plastic or fiber drum, or insert the correct size Diameter Adapter for a smaller drum.

With a Morse forklift attachment, you can easily lift, move and pour a 55-gallon (210 liter) steel drum, with options to handle various other types and sizes of drums. Models are available to dispense a drum weighing up to 1134 kg (2500 Lb.).

Choose from manual tilt controls, powered tilt controls by pendant, or wireless controller as shown.

Install the correct MORCINCHTM Kit to safely handle plastic or fiber drum, or insert the correct size Diameter Adapter for a smaller drum.

Ergonomic

PailPROTM 5-Gallon Pail Truck

PailPROTM 2-wheel pail truck moves a heavy 5-gallon (19 liter) pail with ease. Simply place the pail handle over the hook, pull back on the truck handle to lift with leverage and move the pail. It rolls easily on two 8" (20.3 cm) diameter MORTUF hard polyolefin wheels. For storage, PailPROTM stands upright by itself.

Capacity: 150 Lb. (68 kg)

PailPROTM 2-wheel pail truck moves a heavy 5-gallon (19 liter) pail with ease. Simply place the pail handle over the hook, pull back on the truck handle to lift with leverage and move the pail. It rolls easily on two 8" (20.3 cm) diameter MORTUF hard polyolefin wheels. For storage, PailPROTM stands upright by itself.

Capacity: 150 Lb. (68 kg)

Low Cost, Versatile Drum Lifting and Pouring

Morse 85 Series drum Karriers (stainless steel model 85i-SS available) expedite drum lifting and pouring within reach of the operator. Drum can be rotated 360 degrees by hand. All functions work with a drum faucet in place. The Morse drum holder makes it easy to secure the drum while protecting drum shape.

Morse 85 Series drum Karriers (stainless steel model 85i-SS available) expedite drum lifting and pouring within reach of the operator. Drum can be rotated 360 degrees by hand. All functions work with a drum faucet in place. The Morse drum holder makes it easy to secure the drum while protecting drum shape.

- 85A Series handle a 55-gallon (210 liter) steel drum, and lock drum upright or at 90o

- 85i Series accept kits to add plastic or fiber drum handling, and adapters for a smaller drum. Lock drum at 45o for pouring, in addition to upright, 90o or horizontal position.

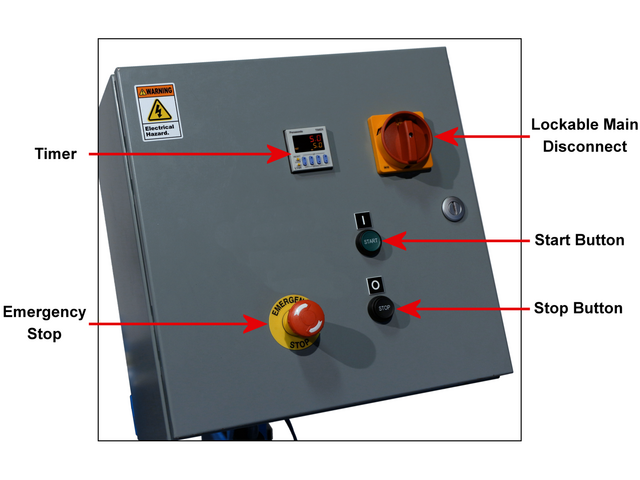

New Drum TumblrTM Control Options Enhance Safety, Ease of Use

Morse Drum TumblrsTM offer a selection of controls and enclosures with interlock. The AC Control Package NEMA 4/12 for NON-Hazardous applications includes a control box with:

Morse Drum TumblrsTM offer a selection of controls and enclosures with interlock. The AC Control Package NEMA 4/12 for NON-Hazardous applications includes a control box with:

- Adjustable timer up to 16 hours

- Start / Stop buttons

- Variable 2 to 20 drum RPM

- Red emergency stop button

- Lockable main disconnect

- Wire terminals to connect safety interlock switch

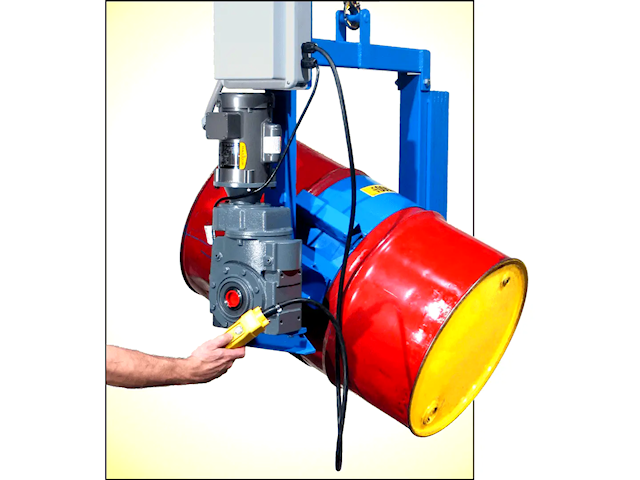

Power-Tilt Below-Hook Drum Carriers... drum tilters and dispensers

Offered in 12 different models, a line of below-hook drum and pail carriers, tilters and dispensers lift, move and pour loads handled by a hoist or crane. The units provide controlled movement and dispensing, as well as load rotation.

All models are load tested to confirm adherence with the American National Standard ASME B30.20 and are supplied with a load test certificate.

Offered in 12 different models, a line of below-hook drum and pail carriers, tilters and dispensers lift, move and pour loads handled by a hoist or crane. The units provide controlled movement and dispensing, as well as load rotation.

All models are load tested to confirm adherence with the American National Standard ASME B30.20 and are supplied with a load test certificate.

MORStakTM Power-Propelled Drum Racker

The < PILOT > Power-Propelled model # 910 walkie stacker moves drums on and off racks, pallets and trucks - and lifts upright drums - for placement in horizontal positions. The unit allows an operator to rack 55-gallon (210 liter) steel or plastic drums (with top rims) to heights up to 10.5 feet (3.2 m).

The unit handles loads up to 800 Lb. (363 kg), and uses precision placement technology to position drums side by side with virtually zero clearance between them. It can also accommodate drums with faucet in place.

The < PILOT > Power-Propelled model # 910 walkie stacker moves drums on and off racks, pallets and trucks - and lifts upright drums - for placement in horizontal positions. The unit allows an operator to rack 55-gallon (210 liter) steel or plastic drums (with top rims) to heights up to 10.5 feet (3.2 m).

The unit handles loads up to 800 Lb. (363 kg), and uses precision placement technology to position drums side by side with virtually zero clearance between them. It can also accommodate drums with faucet in place.

Morse Manufacturing now offers

< PILOT > Power-Propelled Drum Handlers

< PILOT > power-propelled, power lifting and pouring, walk-behind drum handler. The new design provides operator control, productivity, and safety with:

< PILOT > power-propelled, power lifting and pouring, walk-behind drum handler. The new design provides operator control, productivity, and safety with:

- Powered travel speed of 3 mph

- Drum lifting speed of 25 (7.6 m) feet/min

- Drum dumping heights of up to 10.5 feet (3.2 m)

- Dispense 11" (28 cm) beyond the straddle legs

- Handle drum weights up to 1500 Lb. (680 kg)

Stainless Steel Corrosion Resistant Drum Lifter

Morse model 86-SS below-the-hook barrel lifter is now available in type 304 stainless steel for excellent corrosion resistance. This dependable model has long been used in marine, construction, oil, food, chemical and pharmaceutical industries. Now in stainless steel, it will perform better with extended life in corrosive environments.

Morse model 86-SS below-the-hook barrel lifter is now available in type 304 stainless steel for excellent corrosion resistance. This dependable model has long been used in marine, construction, oil, food, chemical and pharmaceutical industries. Now in stainless steel, it will perform better with extended life in corrosive environments.

Does Your Drum Lifter Pass the Test?

Every Morse below-hook drum handler is load tested at the factory at 125% of rated capacity as per American National Standard ANSI/ASME B30.20, and a load test certificate is enclosed with each unit.

Asymmetric Drum Cones

Morse Asymmetric Drum Cones for 55-gallon (210 liter) steel or fiber drums facilitate lifting, tilting and dispensing dry contents from your drum. For superior dispensing control, cones are available with iris valve, slide gate, a valve flange, or just a 6" (15 cm) diameter opening. Choose from either carbon steel drum cones painted blue, or drum cones made of type 304 stainless steel with aluminum bodied iris valve.

Asymmetric Cones work with many Morse models of drum handlers. The asymmetric (offset cone shape) design enables cones to be used with a variety of unmodified below-hook drum handlers. It also extends pouring reach and minimizes the need to fully invert the drum to pour.

Morse Asymmetric Drum Cones for 55-gallon (210 liter) steel or fiber drums facilitate lifting, tilting and dispensing dry contents from your drum. For superior dispensing control, cones are available with iris valve, slide gate, a valve flange, or just a 6" (15 cm) diameter opening. Choose from either carbon steel drum cones painted blue, or drum cones made of type 304 stainless steel with aluminum bodied iris valve.

Asymmetric Cones work with many Morse models of drum handlers. The asymmetric (offset cone shape) design enables cones to be used with a variety of unmodified below-hook drum handlers. It also extends pouring reach and minimizes the need to fully invert the drum to pour.

Heavy-Duty Hydra-Lift Karriers Lift and Dispense

a Drum Weighing up to 1200 Lb. (544 kg)

Now with the Morse Heavy-Duty Hydra-Lift Drum Karrier, you can lift, rotate 360 degrees, and dispense drums weighing up to 1200 Lb. (544 kg) total. You get the advanced productivity of handling hundreds of more pounds when you need to, all on a unit with muscular stability and a compact, maneuverable base.

Lift from various heights up to 72" (183 cm) under AC, air or battery power with maximum ability to handle different drums. With the MORCINCHTM system, drum diameters from 22" to 23.5" (56 to 59.7 cm) OD are promptly secured. Handle steel, plastic and fiber drums, and even small drums with simple adapters.

Now with the Morse Heavy-Duty Hydra-Lift Drum Karrier, you can lift, rotate 360 degrees, and dispense drums weighing up to 1200 Lb. (544 kg) total. You get the advanced productivity of handling hundreds of more pounds when you need to, all on a unit with muscular stability and a compact, maneuverable base.

Lift from various heights up to 72" (183 cm) under AC, air or battery power with maximum ability to handle different drums. With the MORCINCHTM system, drum diameters from 22" to 23.5" (56 to 59.7 cm) OD are promptly secured. Handle steel, plastic and fiber drums, and even small drums with simple adapters.

Wireless Tilt Control Option for Fork-Mounted Drum Racker

To enhance efficiency, tilting control functionality can be easily alternated between wireless option and a direct wire pendant. A strong, 300 foot (90 m) wireless range delivers immediate response without interference from other radio frequency sources. The drum rackers slide quickly onto forks to move drums on and off racks, pallets and trucks with virtually zero clearance between drums. Drums may be handled with faucets in place so that drum racks can also be used as dispensing stations.

To enhance efficiency, tilting control functionality can be easily alternated between wireless option and a direct wire pendant. A strong, 300 foot (90 m) wireless range delivers immediate response without interference from other radio frequency sources. The drum rackers slide quickly onto forks to move drums on and off racks, pallets and trucks with virtually zero clearance between drums. Drums may be handled with faucets in place so that drum racks can also be used as dispensing stations.

Self-Adjusting MORCINCHTM Drum Holder

Morse has announced the MORCINCHTM Drum Handling System, featuring an entirely new drum holder design equipped that:

Morse has announced the MORCINCHTM Drum Handling System, featuring an entirely new drum holder design equipped that:

- Has a unique self-adjusting cinching action to automatically adjust from 22" to 23.5" (56 to 59.7 cm) to include the vast majority of 55-gallon (210 liter) drum diameters

- More secure drum holding

- Durable stress-relief weld joints distribute weight evenly and minimize stress to the drum wall

- Accepts options for plastic or fiber drum

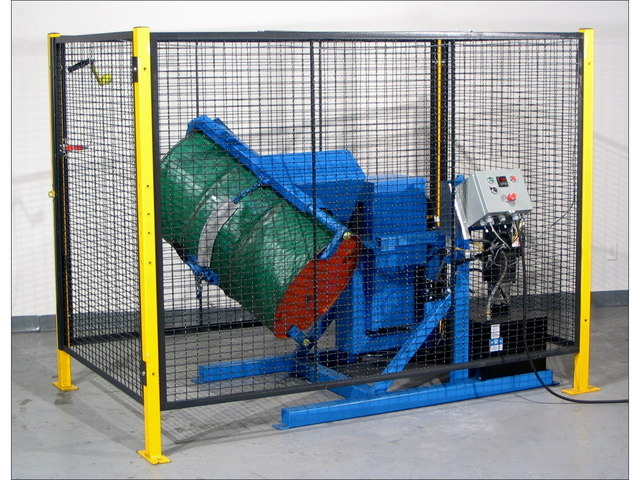

Automated Tilt-To-Load Drum Tumblers with Safety Enclosure

Morse Manufacturing Company offers an online demonstration video and detailed literature describing the "corner-over-corner" drum tumbler with the drum angled off of its center axis for greatest mixing effectiveness.

Tilt-To-Load Drum Tumblers allow floor level loading of an upright drum, and powered raise of drum to rotating position. The advanced Automated Control Package installed by a Morse technician automatically lifts your drum, rotates it for the time you set, and then returns it to upright position at floor-level for easy handling. The built-in safety interlock on the enclosure automatically shuts off the drum rotator when the gate is opened.

Save time and money mixing inside closed steel, plastic or fiber drums of various sizes.

Morse Manufacturing Company offers an online demonstration video and detailed literature describing the "corner-over-corner" drum tumbler with the drum angled off of its center axis for greatest mixing effectiveness.

Tilt-To-Load Drum Tumblers allow floor level loading of an upright drum, and powered raise of drum to rotating position. The advanced Automated Control Package installed by a Morse technician automatically lifts your drum, rotates it for the time you set, and then returns it to upright position at floor-level for easy handling. The built-in safety interlock on the enclosure automatically shuts off the drum rotator when the gate is opened.

Save time and money mixing inside closed steel, plastic or fiber drums of various sizes.

Forklift Attachment to Lift, Transport and Pour a 2500 Lb. (1134 kg) Drum!

Drum handling equipment from Morse Mfg. Co., Syracuse, NY is available to pour a drum weighing up to 2500 Lb. (1134 kg). The Super-Duty Forlift-Karrier attachment converts your fork truck into an efficient drum dispenser. It mates with truck forks without electrical or hydraulic connections or truck modifications. The operator can raise, transport, tilt and drain a fully loaded drum from the driver's seat. Handle a drum with a drum faucet in place and rotate it 360 degrees in either direction.

Drum handling equipment from Morse Mfg. Co., Syracuse, NY is available to pour a drum weighing up to 2500 Lb. (1134 kg). The Super-Duty Forlift-Karrier attachment converts your fork truck into an efficient drum dispenser. It mates with truck forks without electrical or hydraulic connections or truck modifications. The operator can raise, transport, tilt and drain a fully loaded drum from the driver's seat. Handle a drum with a drum faucet in place and rotate it 360 degrees in either direction.

New Patented Clamp+GOTM Dolly Handle

Reduce risks to workers with the ergonomic and safety conscious Morse Clamp+GOTM Dolly Handle. Attach Clamp+GoTM to the sidewall of your drum dolly with a downward push to engage the quick-coupling mechanism. Then pull or push to move your drum around. Easily move into and out of confined areas.

New Clamp+GOTM Revolutionizes Drum Dollying

The Morse Clamp+GO TM drum dolly handle quickly clamps onto dollies with various sized sidewalls, moves them with stunning stability and then can be quickly clamped onto another dolly. Clamp+GOTM is perfect for any drum handling operation and especially for high volume applications.

Reduce risks to workers with the ergonomic and safety conscious Morse Clamp+GOTM Dolly Handle. Attach Clamp+GoTM to the sidewall of your drum dolly with a downward push to engage the quick-coupling mechanism. Then pull or push to move your drum around. Easily move into and out of confined areas.

New Clamp+GOTM Revolutionizes Drum Dollying

The Morse Clamp+GO TM drum dolly handle quickly clamps onto dollies with various sized sidewalls, moves them with stunning stability and then can be quickly clamped onto another dolly. Clamp+GOTM is perfect for any drum handling operation and especially for high volume applications.

In one easy down-push motion, Clamp+GOTM secures itself to your dollys sidewall. The operator then can maneuver the drum with amazing

stability and accident prevention due to the low center of gravity impetus, and push-pull-rotate movements. Disengage with the touch of a boot and

clamp onto the next dolly in seconds.

Safety is greatly enhanced by the low center of gravity reducing tips and spills, plus the handle grip keep fingers from between the drum and other objects. For compact storage the handle can be moved upright to the drum and a magnet keeps it in place.

Morse -- The Specialist In Drum Handling has originated most drum handling advancements and offers the widest product line, plus custom engineered versions, and provides users with the most extensive and expert dealer support network.

Safety is greatly enhanced by the low center of gravity reducing tips and spills, plus the handle grip keep fingers from between the drum and other objects. For compact storage the handle can be moved upright to the drum and a magnet keeps it in place.

Morse -- The Specialist In Drum Handling has originated most drum handling advancements and offers the widest product line, plus custom engineered versions, and provides users with the most extensive and expert dealer support network.

MORStakTM Drum Racker racks drum up to 8.5 feet (2.6 m) high

MORStakTM Drum Rackers for material handling safety

The new MORStakTM drum handler can lift an upright drum, tilt it to the horizontal position, lift it and place it into a drum rack. It just as easily retrieves the horizontal drum and tilts it back to upright. Densest racking is possible because drums are stored horizontally with little space between them.

MORStakTM replaces expensive lift trucks. It eliminates hazardous "bare fork" handling of horizontal drums, upends and down-ends drums, and moves in tighter spaces. Designed for use with typical 55-gallon (210 liter) steel or plastic drums with suitable rims. Recommended for drums as heavy as 800 pounds (363 kg).

Lift and tilt functions are powered. An easy to operate clamp secures drum during tilting. Clamp mechanism has interlock with powered tilt control. Available with a choice of Air or battery power. The MORStakTM drum holder includes clearance for a drum faucet. The 2-stage MORStakTM Drum Rackers provide lift range as high as 102" (259 cm) for a possible four tier drum rack. Single-stage MORStakTM Drum Rackers serve a rack as high as high as 56" (142 cm) including a possible three tier layout.

MORStakTM Drum Rackers for material handling safety

- Eliminate dangerous "bare-fork" drum handling and makeshift upending

- Efficient drum storage and retrieval on multiple tier drum rack

- Transfer drums from vertical to horizontal and back

- Use existing drum-cradle-equipped standard pallet racks

- Place drums side by side with virtually zero clearance

- Maximum utilization of rack space for drum storage

- Rack drum on shelf as High as 102" (259 cm)

- Handle drums where fork trucks cannot go

- Available AC, DC or Air-Powered Hydraulic lifting equipment

- Handle drum with or without faucet

- Service a multi-tier, multi-drum fluid dispensing system

The new MORStakTM drum handler can lift an upright drum, tilt it to the horizontal position, lift it and place it into a drum rack. It just as easily retrieves the horizontal drum and tilts it back to upright. Densest racking is possible because drums are stored horizontally with little space between them.

MORStakTM replaces expensive lift trucks. It eliminates hazardous "bare fork" handling of horizontal drums, upends and down-ends drums, and moves in tighter spaces. Designed for use with typical 55-gallon (210 liter) steel or plastic drums with suitable rims. Recommended for drums as heavy as 800 pounds (363 kg).

Lift and tilt functions are powered. An easy to operate clamp secures drum during tilting. Clamp mechanism has interlock with powered tilt control. Available with a choice of Air or battery power. The MORStakTM drum holder includes clearance for a drum faucet. The 2-stage MORStakTM Drum Rackers provide lift range as high as 102" (259 cm) for a possible four tier drum rack. Single-stage MORStakTM Drum Rackers serve a rack as high as high as 56" (142 cm) including a possible three tier layout.